Cost Savings with Product Customization Tools

As consumer expectations evolve, businesses across industries are shifting toward personalized experiences. From apparel and furniture to automotive and manufacturing, customers now expect products that reflect their preferences.

To meet this demand, companies are adopting product customization tools — digital solutions that enable real-time personalization, improved accuracy, and streamlined production.

Beyond delighting customers, these tools also deliver measurable cost savings. This article explores how configuration and customization platforms help businesses reduce operational expenses, minimize waste, and improve ROI.

Understanding Product Customization Tools

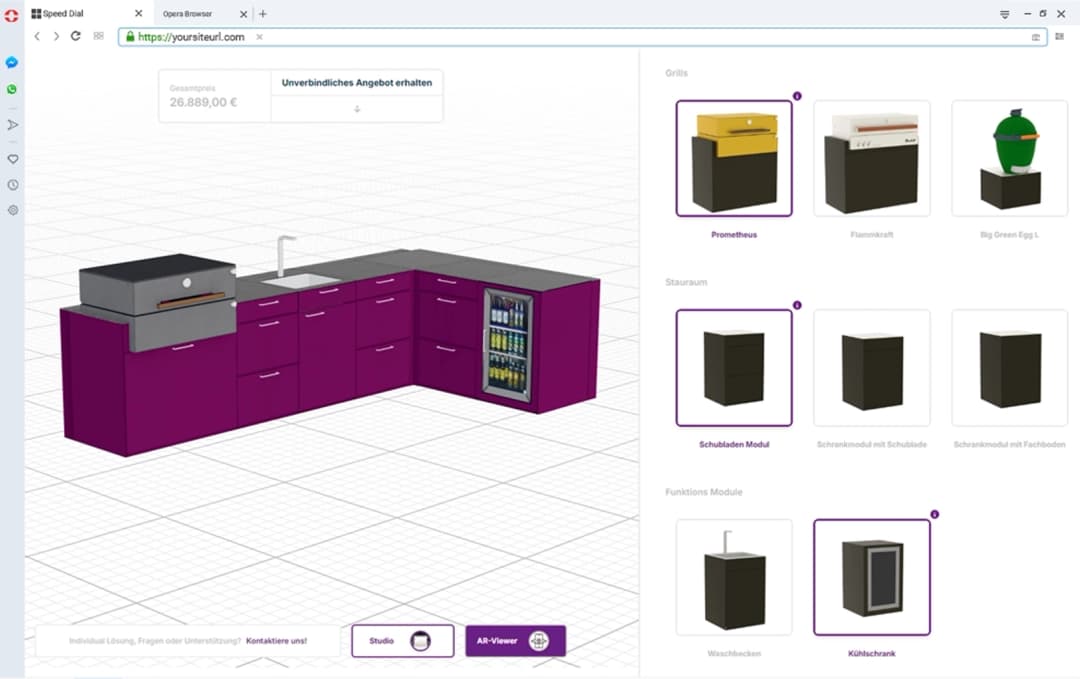

Product customization tools are software solutions that allow customers to tailor a product's design, materials, or features before purchase.

They can include simple 2D interfaces or advanced 3D product configurators with real-time visualization and automated pricing logic.

Key features include:

- Real-time 3D visualization — Customers can rotate, zoom, and preview their choices, reducing uncertainty and design errors.

- Automated pricing & quoting — Instant price updates based on chosen components eliminate manual calculation.

- E-commerce integration — Seamlessly connects with Shopify, WooCommerce, or Magento to sync custom orders directly into checkout.

- Rule logic & validation — Prevents incompatible combinations, ensuring error-free production.

These capabilities make customization tools essential for both customer engagement and operational efficiency.

How Product Customization Reduces Costs

1. Smarter Inventory Management

Traditional production models rely on large pre-built inventories that often result in overstock or obsolescence.

With on-demand manufacturing enabled by customization tools, businesses only produce what is ordered — significantly reducing holding costs and waste.

2. Lower Return Rates

Customers who visualize their product before buying are more confident in their purchase.

This clarity reduces mismatches between expectation and delivery, resulting in fewer returns, lower logistics expenses, and higher satisfaction.

3. Streamlined Production Efficiency

Automation in design and pricing removes the need for manual input between departments.

Engineering, sales, and production teams all access the same configuration data, improving communication and workflow alignment.

4. Reduced Customer Support Workload

With intuitive interfaces that clearly show options and pricing, customers make more informed decisions.

Fewer post-purchase questions or complaints mean lower support costs and faster response times.

5. Data-Driven Supply Chain Optimization

Customization tools provide analytics on customer preferences and order trends.

These insights enable better forecasting, optimized material sourcing, and improved supplier coordination — all contributing to cost efficiency.

Specific Ways Customization Tools Drive ROI

| Cost Area | Savings Impact | Example |

|---|---|---|

| Inventory | On-demand production eliminates excess stock | Apparel brands produce only ordered sizes & colors |

| Production | Automated design files reduce setup time | Manufacturing firms generate CAD/CAM specs instantly |

| Customer Service | Lower complaint volume | 3D previews minimize post-order changes |

| Sales | Faster quote-to-order cycle | CPQ automation helps close deals faster |

| Returns | Reduced return rate | Visual accuracy cuts refund requests by up to 40% |

Case Studies and Real-World Impact

- Custom Apparel: A sportswear manufacturer using a 3D configurator cut unsold inventory by 60% and improved delivery times by 25%. a

- Furniture Industry: Modular furniture retailers implementing guided selling saw a 35% reduction in returns and 20% higher conversion rates.

- Industrial Components: Engineering companies using CPQ software automated their BOM generation, saving hours per order and reducing rework errors.

Conclusion

Product customization tools are far more than a customer-experience upgrade — they’re a strategic cost-saving investment.

By enabling leaner inventory, fewer errors, and real-time automation, these tools optimize every stage of production and fulfillment.

For businesses looking to increase efficiency and profitability, adopting a modern customization or CPQ solution like Konfigear is a proven step forward toward scalable growth.