ERP System Examples

In the ever-evolving landscape of business operations, ERP System Examples serve as beacons of efficiency, integration, and strategic advantage. An ERP system—Enterprise Resource Planning—embodies a suite of software applications that consolidate all facets of a business, from finance to human resources, into a unified platform. This integration allows businesses to streamline processes, improve data accuracy, and foster informed decision-making.

Introduction to ERP Systems

ERP systems have become the backbone of modern business operations, providing a comprehensive solution for managing complex organizational processes. These systems integrate various business functions, creating a seamless flow of information across departments and enabling organizations to operate more efficiently and effectively.

What is an ERP System?

An ERP system is a software framework essential for modern business operations. It integrates various business processes into a single system, encompassing everything from inventory management and order processing to accounting and human resources. By providing a centralized repository of information, ERP systems eliminate data silos, ensuring all departments access consistent, up-to-date information.

The core functionality of an ERP system revolves around its ability to connect different business modules, allowing data to flow seamlessly between departments. This interconnectedness ensures that when a sales order is placed, it automatically updates inventory, triggers production planning, updates financial records, and notifies relevant departments—all without manual intervention.

Benefits of Using ERP Systems

Implementing an ERP system offers numerous benefits. First, it enhances operational efficiency by automating repetitive tasks and standardizing processes. Second, it improves accuracy in data management and reporting, reducing errors and enabling better compliance. Third, it fosters scalability, allowing businesses to grow without the constraints of outdated processes. Finally, ERP systems offer real-time insights, empowering business leaders with the data required to make strategic decisions.

Enhanced Data Accuracy and Reporting

ERP systems centralize data management, ensuring that all departments work with the same accurate, up-to-date information. This eliminates discrepancies that often arise when different departments maintain separate databases. The result is more reliable reporting and better decision-making capabilities.

Improved Process Efficiency and Automation

By automating routine tasks and standardizing processes, ERP systems significantly reduce the time and effort required for daily operations. This automation extends to order processing, inventory management, financial reporting, and human resources functions, freeing up employees to focus on strategic initiatives.

Scalability to Match Business Growth

Modern ERP systems are designed to grow with your business. Whether you're expanding operations, entering new markets, or adding product lines, a well-implemented ERP system can scale to accommodate these changes without requiring a complete system overhaul.

Popular ERP System Examples

SAP ERP

.svg)

SAP ERP stands as a paragon among ERP System Examples, renowned for its comprehensive suite of business solutions. It offers modules for financial management, supply chain management, and more. SAP Business Suite is tailored to both large enterprises and small businesses, providing scalable solutions that adapt to business needs. The robust architecture of SAP ERP supports complex business processes, making it a preferred choice for multinational corporations.

SAP's modular approach allows organizations to implement specific modules based on their requirements, such as SAP Financials, SAP Human Capital Management, or SAP Supply Chain Management. This flexibility, combined with SAP's extensive customization capabilities, makes it suitable for businesses across various industries and sizes.

Oracle ERP Cloud

Oracle ERP Cloud exemplifies the integration of modern technology with traditional business functions. This cloud-based ERP solution offers unparalleled flexibility and accessibility, allowing businesses to operate with agility. With modules covering financials, procurement, and project management, Oracle ERP Cloud caters to a diverse range of industries. Its emphasis on security and compliance makes it a trusted partner for organizations seeking robust cloud solutions.

Oracle ERP Cloud's strength lies in its comprehensive financial management capabilities, advanced analytics, and seamless integration with other Oracle cloud services. The platform's AI-powered features provide intelligent insights and automation, helping organizations optimize their operations and make data-driven decisions.

Microsoft Dynamics 365

Microsoft Dynamics 365 merges CRM and ERP capabilities into a singular cloud platform. This integration fosters a seamless flow of information across business units, enhancing customer engagement and operational efficiency. Dynamics 365 is particularly beneficial for small businesses due to its modular approach, allowing companies to implement only the functionalities they need. Its deep integration with other Microsoft products ensures a familiar user experience.

The platform offers various modules including Finance and Operations, Sales, Customer Service, and Supply Chain Management. This unified approach enables organizations to manage both customer relationships and internal operations from a single platform, creating a 360-degree view of the business.

Industry-Specific ERP Systems

Manufacturing Industry

The manufacturing sector benefits immensely from ERP systems tailored to its unique demands. Manufacturing-focused ERP solutions streamline production planning, inventory management, and quality control. By integrating these processes, manufacturers can reduce waste, optimize resource utilization, and accelerate time-to-market. Examples of such ERP software include Epicor and Infor, which are designed to meet the intricate needs of manufacturers.

Manufacturing ERP systems typically include advanced features such as material requirements planning (MRP), capacity planning, shop floor control, and quality management. These features enable manufacturers to optimize production schedules, manage complex supply chains, and maintain high quality standards while minimizing costs.

Healthcare Industry

Healthcare institutions leverage ERP systems to enhance patient care and operational efficiency. These systems manage patient records, scheduling, billing, and compliance with regulatory standards. ERP software like SAP Healthcare and Oracle Healthcare allow healthcare providers to deliver better patient outcomes by ensuring data accuracy and accessibility. The integration of clinical and administrative processes is pivotal in maintaining high standards of healthcare delivery.

Healthcare ERP systems must comply with strict regulations such as HIPAA in the United States, making security and compliance critical features. These systems help healthcare organizations manage complex billing processes, track patient care, manage medical supplies, and ensure regulatory compliance while improving operational efficiency.

Retail Industry

Retailers utilize ERP systems to manage inventory, point of sale, customer relationships, and supply chain operations. By centralizing these functions, retailers can optimize stock levels, enhance customer experience, and improve supply chain visibility. Solutions like Microsoft Dynamics 365 for Retail and NetSuite ERP are popular choices for retailers aiming to streamline operations and drive profitability.

Retail ERP systems often include features such as multi-channel commerce support, inventory optimization, customer loyalty programs, and real-time sales analytics. These capabilities enable retailers to provide seamless shopping experiences across online and physical stores while maintaining optimal inventory levels and understanding customer preferences.

Choosing the Right ERP System

Factors to Consider

Selecting the appropriate ERP system is crucial for business success. Considerations include the size of the business, industry-specific requirements, budget constraints, and the scalability of the software. It's essential to evaluate the ERP software's functionality in aligning with business objectives, ensuring a return on investment and supporting long-term growth.

Key factors to evaluate include:

- Business Size and Complexity: Small businesses may need simpler solutions, while large enterprises require comprehensive platforms with advanced features.

- Industry Requirements: Some industries have specific compliance and operational needs that require specialized ERP modules.

- Budget and Total Cost of Ownership: Consider not just the initial licensing costs but also implementation, training, maintenance, and upgrade expenses.

- Integration Capabilities: The ERP system should integrate seamlessly with existing software and systems.

- Vendor Support and Reputation: Choose a vendor with a proven track record and strong customer support.

Implementation Challenges

Implementing an ERP system is a complex endeavor, often fraught with challenges. Common issues include data migration, user resistance, and cost overruns. Successful implementation requires meticulous planning, stakeholder engagement, and ongoing support. Overcoming these challenges is vital to realizing the full potential of an ERP system and achieving operational excellence.

Common implementation challenges include:

- Data Migration: Transferring existing data to the new system while maintaining data integrity

- Change Management: Overcoming user resistance and ensuring proper training

- Customization Complexity: Balancing customization needs with standard functionality

- Timeline Management: Avoiding delays that can impact business operations

- Budget Management: Controlling costs and avoiding scope creep

Future Trends in ERP Systems

Cloud-Based ERP Solutions

The advent of cloud-based ERP solutions marks a significant shift in business technology. These solutions offer flexibility, scalability, and cost-effectiveness, making them ideal for small businesses and large enterprises alike. The ability to access ERP systems from anywhere enhances operational agility and supports remote work environments. As cloud technology evolves, so too will the capabilities of cloud-based ERP systems.

Cloud ERP solutions eliminate the need for extensive IT infrastructure, reduce upfront costs, and provide automatic updates and maintenance. This makes enterprise-level functionality accessible to businesses of all sizes, democratizing access to powerful business management tools.

AI and Machine Learning in ERP

The integration of AI and machine learning within ERP systems promises transformative changes. These technologies enable predictive analytics, process automation, and enhanced decision-making capabilities. AI-driven insights can identify patterns and trends that humans might overlook, providing a competitive edge in a data-driven world. As AI continues to advance, its role within ERP systems will become increasingly critical.

AI-powered ERP features include:

- Predictive Analytics: Forecasting demand, identifying potential issues, and optimizing inventory

- Intelligent Automation: Automating routine tasks and decision-making processes

- Natural Language Processing: Enabling voice commands and conversational interfaces

- Anomaly Detection: Identifying unusual patterns that may indicate problems or opportunities

Key Benefits Summary

- Enhanced data accuracy and reporting

- Improved process efficiency and automation

- Scalability to match business growth

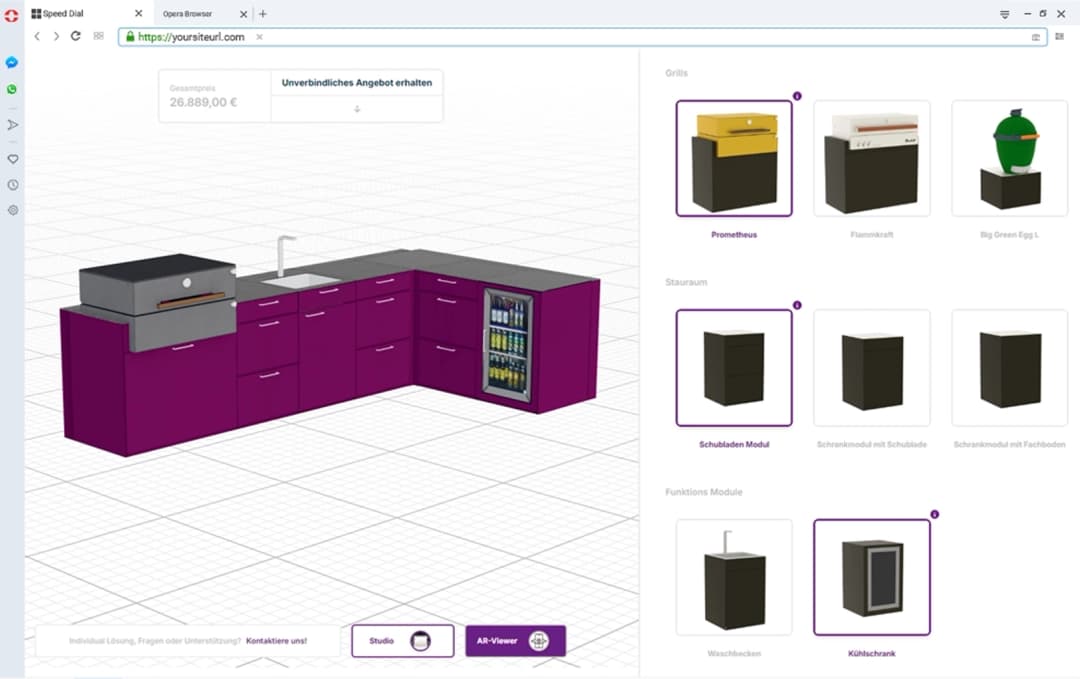

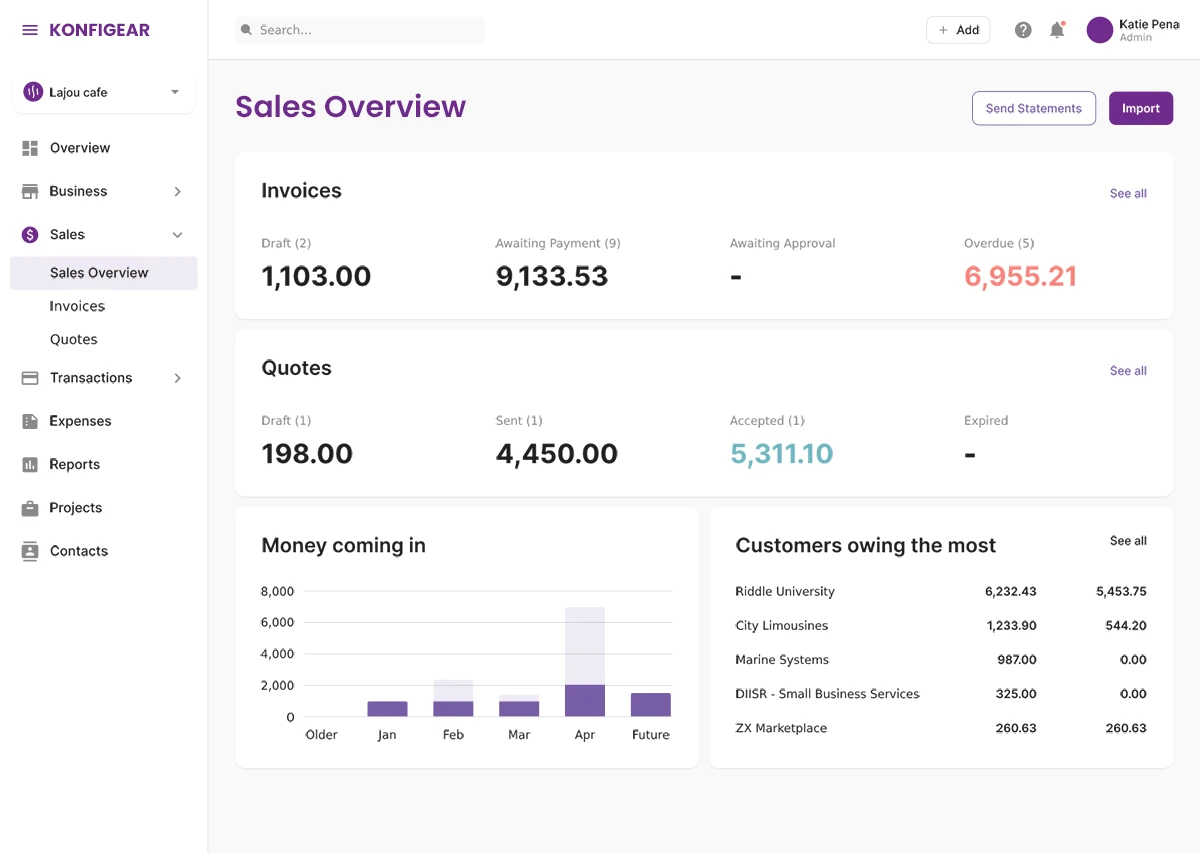

Diagram illustrating the components of an ERP system.

Conclusion

ERP systems represent a critical investment for modern businesses seeking to streamline operations, improve efficiency, and gain competitive advantages. From comprehensive solutions like SAP and Oracle to industry-specific platforms, the right ERP system can transform how organizations operate and compete in their markets. As technology continues to evolve, cloud-based solutions and AI integration will further enhance the capabilities of ERP systems, making them even more valuable for businesses of all sizes.

For further reading on the impact of ERP systems on modern business, consider exploring resources such as Gartner's ERP Glossary.