Cost Savings with Product Customization Tools: Maximize ROI

As consumers increasingly demand products tailored to their preferences, businesses across industries are turning to product customization tools. These digital solutions enable companies to offer personalized items, from custom apparel to configurable industrial parts, allowing customers to make specific selections that reflect their needs and tastes.

While customization itself enhances customer satisfaction, there's a lesser-known benefit of using these tools: Cost savings with product customization tools. This article explores the role of product customization tools in driving down operational costs and improving efficiency. We’ll dive into how these tools reduce expenses in inventory management, production, and customer service while increasing the return on investment (ROI) through streamlined workflows and data-driven decisions.

Understanding Product Customization Tools

Product customization tools are software solutions that allow businesses to provide tailored products by letting customers make individual choices. From selecting colors and materials to configuring complex technical specifications, these tools transform a static product list into a dynamic, user-centric experience.

Key features of these tools include:

Real-time 3D visualization

Customers can see exactly how their choices will look, reducing the chances of dissatisfaction.

Automated pricing

Prices adjust instantly based on chosen features, eliminating the need for manual calculations

E-commerce integration:

Many customization tools connect directly with online storefronts, creating a seamless purchase process.

With personalized products now expected by many customers, these tools are becoming invaluable to businesses aiming to stand out while optimizing their cost structures.

The Impact of Product Customization on Cost Savings

Customization tools are not only for enhancing customer satisfaction but are also powerful cost-saving mechanisms. Here’s how they impact costs:

Inventory Management

Traditional models require stocking a range of products to meet varied customer demands. However, customization tools enable on-demand production, reducing the need to hold excess inventory. This approach minimizes inventory holding costs and reduces waste from unsold items.

Reduced Return Rates

With customization, customers are more likely to receive precisely what they want, leading to fewer returns. This accuracy not only saves on restocking and shipping costs but also improves customer satisfaction.

Efficient Production

Customization tools streamline production by automating configuration and design processes. This allows manufacturers to produce items only when an order is placed, decreasing material waste and optimizing labor allocation.

Streamline workflow communication across departments

Groups like sales, engineering, and manufacturing access the latest custom order details.

Specific Ways Product Customization Tools Help Cut Costs

With accurate build specifications applied directly to production, configurators enable outstanding responsiveness and scalability.

Automated Pricing and Quoting

Product customization tools include features for real-time pricing, which adjusts instantly based on customer selections. This not only speeds up the sales process but also reduces labor costs associated with manual quotes, allowing sales teams to focus on closing deals instead of calculating prices.

Decreased Customer Support Costs

Clear, user-friendly customization tools empower customers to make informed choices, reducing the likelihood of post-purchase inquiries and complaints. With fewer queries, businesses can reduce the volume of customer support tickets, saving time and labor in this department as well.

Streamlined Manufacturing Process

Many customization tools support direct-to-manufacturing workflows, where customer orders are automatically transformed into production-ready specifications. This automation cuts down production time and reduces labor costs by minimizing the need for manual interventions in the production cycle.

Enhanced Inventory and Supply Chain Management

Customization tools provide detailed data insights into production trends and customer preferences, helping businesses make more accurate inventory forecasts. This data-driven approach minimizes overproduction, reduces storage needs, and optimizes supply chains, leading to inventory savings.

Case Studies and Real-World Examples

Real-world examples underscore the tangible cost savings these tools can bring to businesses. Below are some cases where companies successfully implemented customization tools and saw substantial savings:

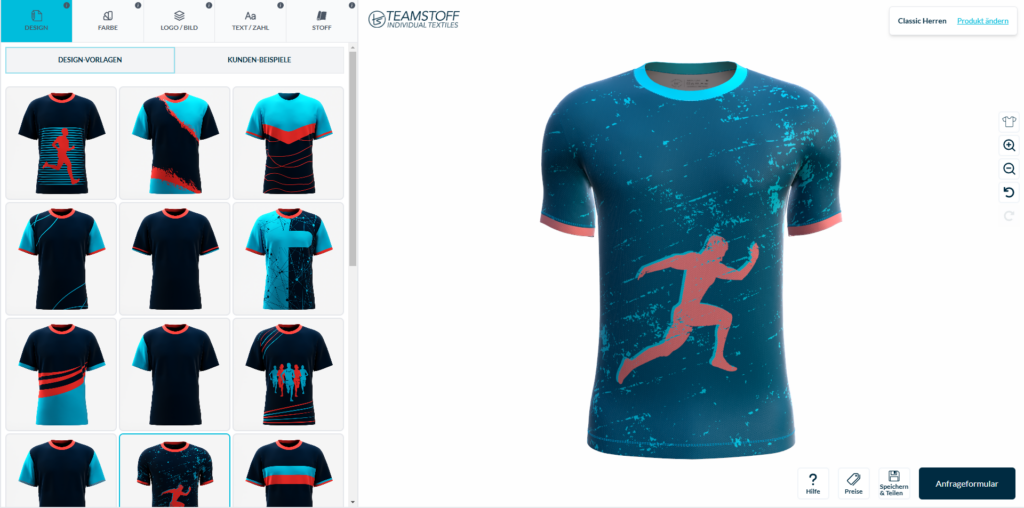

Case Study 1: TEAMSTOFF Individual Textiles

A fashion retailer, implemented a customization platform for on-demand garment printing. By adopting an on-demand model, they cut their inventory holding costs by 43.5% and reduced return rates by 35% as customers could design their items to fit personal style preferences.

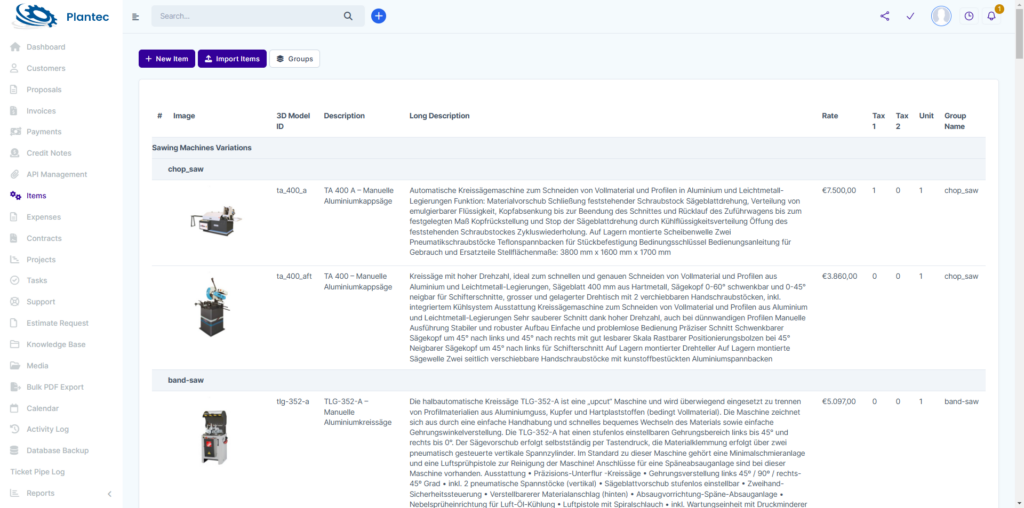

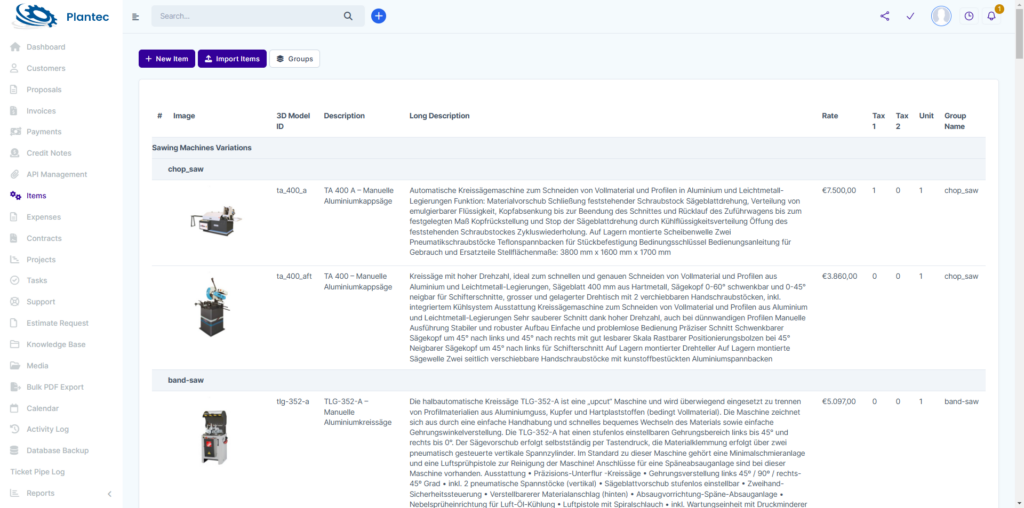

Case Study 2: Plantec Gmbh Manufacturing

a custom roller machinery producer, integrated a 3D configurator with automated pricing for their product line. This allowed them to cut quote processing times by 50% and lower labor costs associated with manual quoting and specification adjustments.

Case Study 3: LMN Home Goods

A home furnishing company, used a customization tool that provided real-time inventory insights, reducing their need for excess raw materials by 25%. They also noticed a 10% improvement in order accuracy, which led to fewer product returns.

Key Metrics to Measure ROI on Product Customization Tools

Tracking cost savings and efficiency gains is critical to understanding the value of customization tools. Here are several metrics that can help businesses assess ROI:

Inventory Turnover Rate

Measures how quickly inventory is sold and replaced over time. High turnover indicates that products are moving efficiently, which is beneficial in a customization-based production model.

Return on Inventory Investment (ROII)

This metric evaluates the profitability of inventory. By comparing profit from sales to inventory holding costs, businesses can assess how much customization tools contribute to effective inventory management.

Order Accuracy Rate

A high accuracy rate reflects fewer returns and less waste, key indicators of cost-saving through customization.

Choosing the Right Product Customization Tool for Cost Efficiency

These metrics measure how well customization meets customer expectations, correlating directly with long-term cost savings by reducing returns and increasing repeat purchases.

Case Studies: Manufacturing Success with Configurator Technology Product Configurators

Selecting the right customization tool is critical to maximizing cost savings. Here are key factors businesses should consider:

Integration Capabilities

Look for software that integrates smoothly with existing e-commerce and ERP systems, ensuring seamless data flow across departments.

Ease of Use

The tool should offer an intuitive interface for both customers and internal teams to reduce the need for extensive training.

Scalability

Choose a tool that can adapt to future growth, whether that means handling more SKUs or expanding into new customization features

Cost and Support

Evaluate the tool’s pricing structure and customer support. Choosing a cost-effective tool with strong customer support can save money on troubleshooting and allow for smoother implementation

Potential Challenges and How to Overcome Them

Customization software that aligns with a business's unique needs can optimize cost savings across multiple fronts.

Implementing product customization tools isn’t without challenges. However, many of these obstacles can be overcome with careful planning:

Initial Cost of Implementation

Customization tools require an upfront investment. To manage costs, businesses can consider phased rollouts that allow for gradual scaling.

Training Requirements

New software can necessitate extensive staff training, which incurs costs. Opt for tools with user-friendly interfaces and comprehensive vendor support to ease the learning curve.

System Integration Challenges

Complex software integrations can lead to delays and additional expenses. Choosing customization tools with established integration capabilities can mitigate these issues, ensuring smoother deployment.

Final Words

Product customization tools offer far more than a way to cater to customer preferences—they provide substantial cost-saving opportunities that can benefit businesses across industries. From reducing inventory and labor costs to enhancing production efficiency, these tools allow companies to streamline operations and make data-driven decisions that reduce waste and improve ROI.

As companies look to innovate and stay competitive, customization tools emerge as a powerful investment with significant long-term savings potential. Consider taking the first step toward a leaner, more efficient business model by evaluating the right customization tools for your organization.

Ready to start saving? Explore the latest product customization tools and see how they can transform your business today.